What is the digital factory?

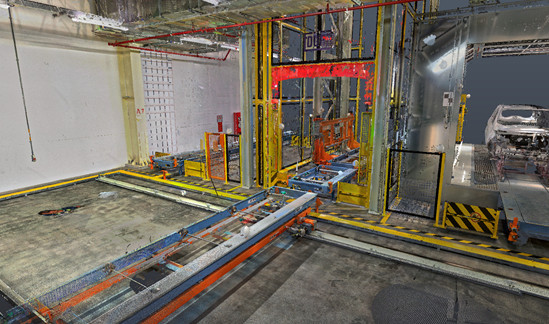

The digital factory is a virtual copy of a future or present factory (as-built documentation) including all machines, production lines, installations and services. In the digital factory, all objects and production lines of the factory are fully visualized in 3D.

Laser scanning in the digital factory and plant construction

More often than not, only incomplete plans of existing factories and plants can be provided. Furthermore, plans are usually not updated over the course of a factory and plant planning. Nowadays, however, factories and plants can be scanned and visualized in a three-dimensional world. That being the case, planners’ and engineers’ tasks are simplified while time and effort is substantially reduced.

One of many advantages is the fact that the ongoing production processes need not to be stopped during modernization projects or modifications of industrial plants and installations. It is within a long distance to objects and installations that laser scanning enables contactless and fast 3D scans, which can be used for plant planning. The geometrical data of machines and pipes are then extracted and visualized through a CAD system.

Laser scanning is the modern way for the digital factory

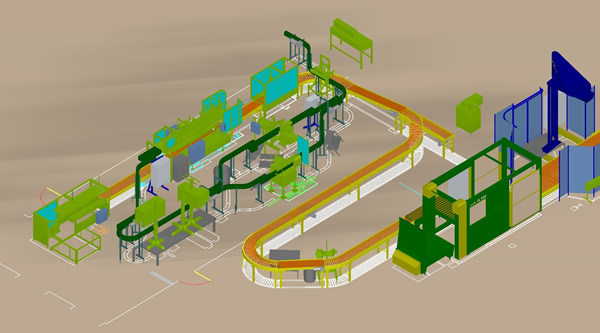

The digital factory serves to optimize processes within the factory during both the planning phase and ongoing production processes. This applies to product development, production management, work equipment, resources, time and costs.

Buildings are visualized three-dimensionally down to the last detail to perform collision detections and ensure efficient layout planning. After the production processes have been implemented into the factory layout, collision detections can then be performed. Finally, the modifications and adaptations are visualized. It therefore follows that laser scanning has become an invaluable resource for layout planning.

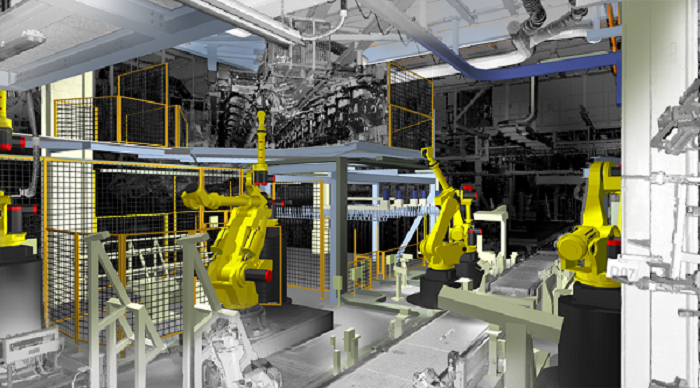

Production processes are simulated with the digital factory; and after that they will be analyzed and optimized. That way, it is a simple matter to integrate a new robot into an existing installation or plant. These services can also used for building services. For example, it is possible to determine the amount of air that passes through a ventilation system at a given time frame.

The geometrical data is stored in a 3D database and is then available for future adaptations and alterations of the factory. The database can be updated and expanded any time. Thanks to durable and readily available representations within the CAD program, planning speed and quality are significantly improved.

Advantages of laser scanning in the digital factory and plant construction

More and more companies use laser scanning for modern plant construction projects. This is not only because it is a tremendous time and cost saver, but also due to the possibility to make fast and simple planning decisions. Furthermore, it delivers highly accurate and photo-realistic results. The planning of the digital factory is substantially improved through the possibility to scan existing factories in three-dimensional space and transfer the results into CAD systems; finally, the replanning of the factory is done on the basis of the model.

Advantages at a glance:

- easy

- fast

- extremely accurate

- photo-realistic

- complete

- contactless

- not dependent on light

- repeatable

- economical